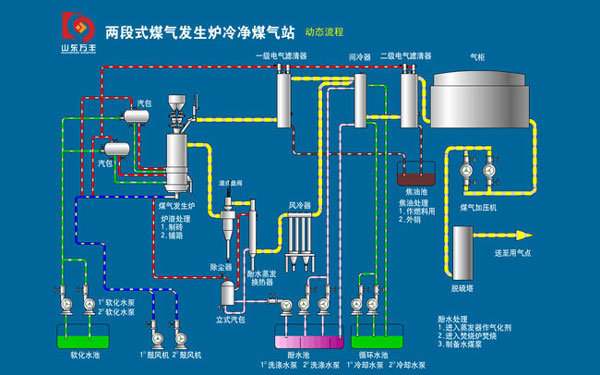

Two-stages coal gasifier is of continuous gas-making and air blowing type. Self produced low-pressure steam,phenol vapor from phenol-water-vaporizer and bowled air will be mixed as gasification agent. The saturated steam temperature is controlled between 55℃ and 65℃. It gets though dry type check valve, windpipe on gasifier bottom, fire grate and then enters into the gasifier. In gasification stage, it meets semi-coke formed by raw coal fed conversely, and results in gasification reactions and generates hot gas. About 65% hot gas gets out though centre steel pipe and channels inside ring-shaped gasifier brick wall, which is called down-stage gas. The rest 35% directly heat up, dry and distil the raw coal in dry distillation stage. And then the hot gas is mixed with distillation gas and result in up-stage gas.

1. Form of up-stage gas

Coal fed into gasifier is heated by hot gas produced in gasification stage. It first lots inside and outside moisture (90~150℃), and then volatilizes the volatile matter after being dry distilled (150-550℃). The volatile matter contents tar, paraffin gas, phenol and the mixture of H2, CO2, CO and H2O. There into, tar and light oil is separated when up-stage gas gets into following decontamination, and distillation gas including paraffin gas, H2, CO2, CO mixes with gasification gas and then results in up-stage gas.

2. Decontaminating and cooling process of up-stage gas

Up-stage gas get into electrical detarrer whose work temperature is about 90~150℃. In this part, heavy tar is separated (the heating value can beyond 8200Kcal/kg). Output of tar is 2~3% of gross raw coal, varying according to different kinds of coal; and it is high quality chemical material and fuel. After primary detarring, the up-stage gas gets into indirect cooler, where the gas is cooled to below 45℃ and gives birth to phenol water mixture containing light oil. The light oil can be separated because it is lighter than phenol water. Then the up-stage gas gets into electrical deoiler, where the light tar fog-drop and dust is polarized, then influxes on inside wall of polar tube and finally flows automatically to tar pond. The content of light tar is equal to heavy diesel oil.

3. Form of down-stage

Raw coal is dry distilled by bottom gas in distillation stage, which gives birth to semi-coke, and then gets into gasification stage. The volatile matter contented in semi-coke is about 3~5%. Gasification activity of semi-coke is lower than bituminous coal because semi-coke has lost activity content. The gasification capacity can reach 250~320Kg/m2.h, and temperature in gasification fire layer of two-stage gasifier is usually between 1000~1300℃. Semi-coke and steam or air arises following actions:

C + O2 = CO2 + 408840 kJ/kmol

C + 1/2O2 = CO + 123217 kJ/kmol

CO2 + C = 2CO – 162405 kJ/kmol

C + H2O = CO + H2 – 118821 kJ/kmol

C + 2H2O = CO2 + 2H2 – 75237 kJ/kmol

Bottom gas is totally gasified gas, in which contents little tar and dust. Its heating value is about 1200~1300 Kcal/Nm3. According to gasification theory, the higher temperature is or the thicker fire layer is, the higher the heating value is, vice versa.

4. Decontaminating process of down-stage gas

Firstly, dust is centrifugally separated by cyclone dust cleaner and gas temperature is lowered to ≤550℃; secondly, the gas comes into phenol water evaporating heat exchanger to recover the gas sensible heat with the temperature dropping to ≤230℃; Thirdly, the gas temperature is dropped to ≤150℃ in wind cooler; and finally, its temperature is lowered to ≤45℃ by circulatory cooling water in indirect cooler. Then down-stage gas is mixed with up-stage gas and gets into electrical deoiler to have a second removing of oil and dust. And the cold gas coming into low pressure main pipe, is pressed by booster fan, and finally goes to use point through desulphurizing system to remove some extent of sulphur.